When you're running a small apparel business or printing custom merch for clients, the right press makes the difference between pro results and wasted time. You want consistent adhesion, even heat, fast cycle times, and a machine that stands up to repeat use. best heat press for dtf transfers should be easy to dial in, work with different garments, and integrate into a same-day production workflow.

In this guide you'll get practical buying advice, press features that matter for DTF, recommended press types for different budgets and volumes, reliable starting settings to test, and FAQs to remove guesswork. If you sell shirts, hoodies, or stickers and need fast, press-ready DTF transfers, this article helps you choose the right heat press and get consistent results.

Why a dedicated DTF-ready heat press matters

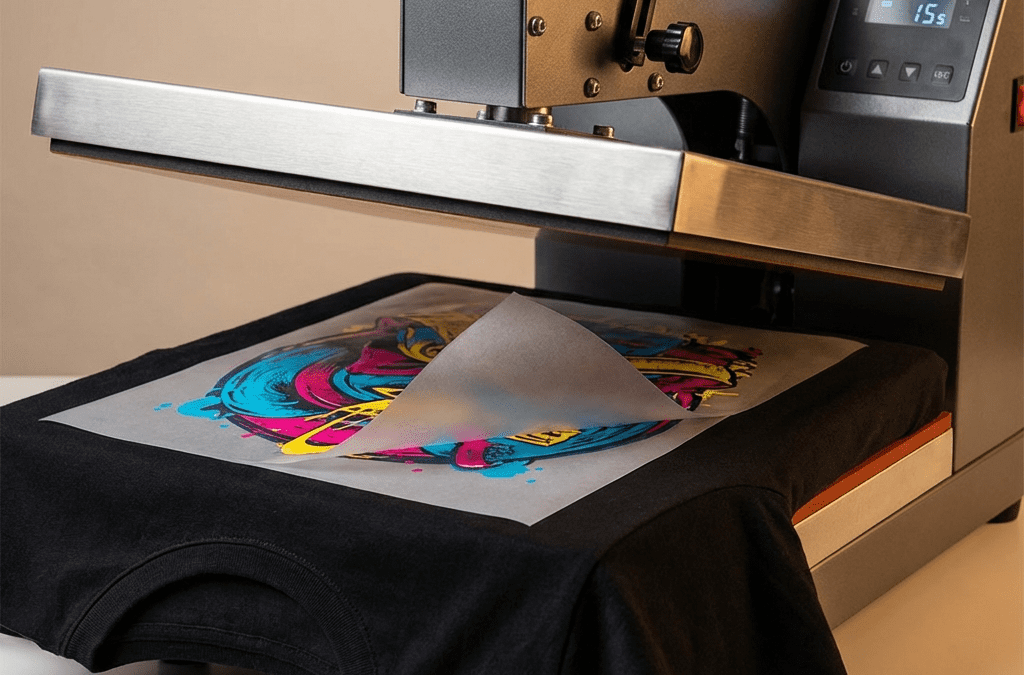

DTF transfers behave differently than direct-to-garment or vinyl. They need even heat across the platen, stable pressure, and repeatable cycles so the adhesive melts and bonds without scorching or ghosting. The wrong press wastes transfers, increases rejects, and slows turnaround. Pick a press built for production, not just weekend crafting.

Key features to prioritize

- Platen size, choose based on your typical print size. A 16×20 platen covers most tees and hoodies, 12×15 or 15×15 is fine for smaller shops. Larger platens speed production for gang sheets.

- Even heat distribution, digital temperature control, and an accurate PID controller for stable results.

- Pressure adjustability, clear gauge or dial, and consistent platen parallelism so prints adhere evenly.

- Type of press: clamshell for space and speed, swing-away for thick or delicate fabrics, pneumatic for high-volume repeatability.

- Quick heat-up time and tight temperature hold for same-day jobs.

- Durable construction and replaceable silicone or Teflon platens for easy maintenance.

Types of presses and who they are best for

Clamshell heat presses

Best for: small shops and beginners who need compact, quick presses. Clamshell presses close like a clamshell which saves space and is simple to use. They are fast for short runs but watch pressure consistency across the platen.

Swing-away heat presses

Best for: operators who press hoodies, thick seams, or want full, flat heat contact. The platen swings clear so you can position transfers precisely. Ideal for higher-quality prints where even pressure matters.

Pneumatic and industrial presses

Best for: high-volume shops and production lines. Pneumatic presses deliver consistent pressure every cycle and are built to last. They’re a bigger investment, but you get speed and uniformity for large batches or same-day turnaround.

How to choose by budget and production needs

- Starter / hobbyist (low volume): 15×15 clamshell press, digital temp control, platen heat evenness check. Expect lower price, great for samples and occasional orders.

- Small business / Etsy sellers (moderate volume): 16×20 swing-away or clamshell with a solid build, consistent heat, and better pressure controls. Good balance of capacity and price.

- Production shop / print business (high volume): pneumatic or heavy-duty swing-away, 16×20 or larger, reliable PID control, and quick change platens to run gang sheets.

Recommended press features and accessories

- Replaceable Teflon or silicone platen cover to protect prints.

- Heat-resistant teflon sheet or parchment for overlays, depending on your transfer type.

- Pressure gauge or digital pressure settings for reproducible results.

- Extra platens or larger platen option for gang sheets and sticker runs.

- Vacuum table or platen alignment jig for multi-up prints and sticker registration.

Starting DTF press settings and a test protocol

Every transfer, film brand, and garment is different, so always test. Here’s a practical starting point you can use as a baseline, then adjust in small steps:

- Temperature range to test: 300–330°F. Start conservative and work up if under-adhesion appears.

- Press time to test: 8–15 seconds for initial contact, then consider a short cooling period and a final press for some films.

- Pressure: medium to firm, enough to make full contact without crushing fabric texture.

- Peel method: follow your film maker’s specs, some DTF films are hot-peel while others recommend cold peel after cooling.

Tip, do a four-square test: press four small prints at different temperatures or times on the same garment quadrant to compare results quickly.

Best practices for consistent DTF results

- Prepress garments for 3–5 seconds to remove moisture and wrinkles.

- Use a heat-resistant cover sheet where needed to prevent shine or scorching.

- Keep a log: record temperature, time, pressure, film brand, and peel method for each test.

- Maintain your press: recalibrate temperature, replace worn platens, and keep the heating element clean.

Where to buy supplies and fast-turn transfers

If you need ready-to-press transfers, fast shipping, or same-day local pickup in Tempe, check out Five Star DTF for DTF Transfers, UV DTF Stickers, and Glitter DTF Transfers. They support small businesses with no minimums and fast turnaround: DTF Transfers, UV DTF Stickers, Glitter DTF Transfers.

Frequently asked questions

What is the best platen size for DTF transfers?

Choose a platen based on your most common print size. For T-shirts and hoodies, 16×20 gives the most flexibility for single prints and gang sheets. Smaller shops may prefer 15×15 for space savings.

Can I use a standard heat press for DTF or do I need a special machine?

You can use many standard presses for DTF, but pick one with even heat and reliable pressure. Swing-away models reduce risk of accidental movement and are friendlier for thicker garments.

What temp, time, and pressure work for DTF transfers?

Start with a conservative test range: 300–330°F and 8–15 seconds at medium-firm pressure. Always test with your specific film and garment, and log results for repeatability.

Is a pneumatic press worth the investment?

Yes if you run consistent daily volume. Pneumatic presses provide repeatable pressure, faster cycle times, and less operator fatigue, so they pay for themselves in production efficiency.

How do I prevent scorching or ghosting?

Prepress to remove moisture, use a protective Teflon sheet if needed, and avoid excessive pressure or too-high temperatures. Test different combinations until you find the sweet spot.

Where can I get press-ready DTF transfers with fast shipping?

Five Star DTF offers same-day printing and local pickup in Tempe with nationwide shipping and free shipping over $100. Upload artwork and get press-ready transfers quickly at their product pages.

Get production-ready fast

Ready to upgrade your workflow and remove the guesswork? Five Star DTF prints press-ready transfers in Tempe with fast same-day production and dependable color. Order online for quick turnaround or pick up locally.

Order online: https://fivestardtf.com/product/dtf-transfers/

📍 Local pickup: 305 S Rockford Dr Ste B, Tempe, AZ 85281

For technical help and press instructions, see our step-by-step guide at Press Instructions & Tips or contact us at Contact & Local Pickup.

Conclusion

Choosing the best heat press for DTF transfers comes down to matching the machine to your volume and product mix. Prioritize even heat, reliable pressure, and a platen size that fits your most common jobs. Start with conservative settings, test, and keep good records. If you want ready-made transfers, same-day printing, or help dialing in settings, Five Star DTF in Tempe is set up for quick turnaround and pro results.

About Five Star DTF

Five Star DTF is Arizona’s leading provider of

DTF transfers, Glitter DTF prints, UV DTF stickers,

and Sublimation transfers — offering same-day printing, fast nationwide shipping,

and convenient local pickup in Tempe, Arizona.

We proudly serve Tempe, Scottsdale, Phoenix, Mesa, Gilbert, Chandler, and all of Arizona,

helping creators, apparel brands, small businesses, and print shops produce premium, press-ready transfers with

vivid color, soft stretch, and long-lasting durability.

There are no setup fees, no minimum orders, and turnarounds are always fast.

Our Top Products

- DTF Transfers

- Glitter DTF Transfers

- UV DTF Stickers

- Sublimation Transfers

- Press Instructions & Tips

- Contact & Local Pickup

Artwork Help

Need your artwork cleaned, fixed, resized, or made print-ready? We offer background removal, vectorizing, color correction, and gang sheet layout.

Ready to Print?

Order DTF Transfers or

Upload Your Artwork to get started today.

All orders over $100 ship free — printed in Tempe, AZ and shipped statewide and nationwide.