When you need reliable, vibrant prints that work on both everyday tees and performance gear, the right Direct-to-Film workflow makes all the difference. This guide walks you through how to get consistent, press-ready results with dtf prints for cotton and polyester, whether you’re a small shop in Tempe or an Etsy seller shipping nationwide.

Why DTF Works Great on Both Cotton and Polyester

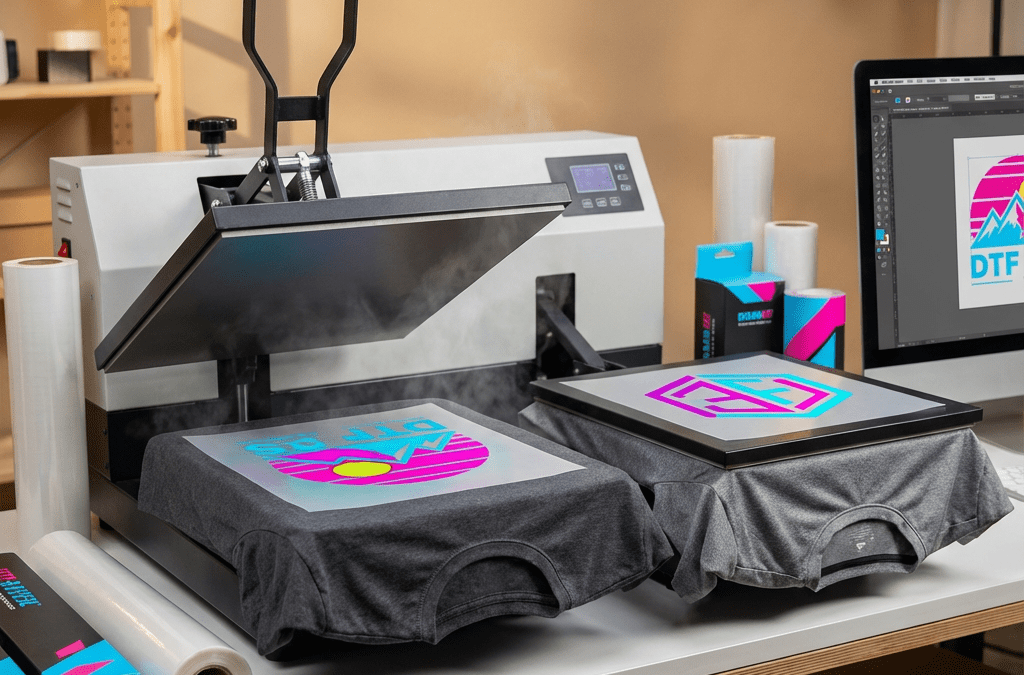

DTF (Direct-to-Film) transfers are printed on PET film with CMYK plus white ink and a powdered adhesive. After curing, these films press onto fabric to produce full-color, soft-feel images. The process is fabric-agnostic, which means it works on cotton, polyester, blends, nylon, and spandex. That versatility is why many small brands and print shops choose DTF as their go-to method for mixed-fabric runs.

Benefits at a glance:

- True full-color photo quality on light and dark garments.

- Soft, stretch-friendly finish that doesn’t crack like vinyl.

- No special pre-treatment for most fabrics, including polyester.

- Quick turnaround, low minimums, and gang-sheet flexibility.

Fabric Differences: What to Expect

Cotton

Cotton soaks up heat well and gives exceptionally smooth results. Colors appear rich and vibrant because the adhesive bonds securely to the fabric fibers. Expect excellent wash durability when pressed correctly.

Polyester

Polyester is heat-sensitive but responds well to DTF because the adhesive layer bonds to the synthetic fibers without the need for dye-sublimation. You’ll see slightly brighter whites and color pop on performance fabrics, but be careful with temperature and dwell time to avoid garment scorching or shine.

Recommended Heat Press Settings (Pro-tested)

Follow these general settings as a starting point, then test on a fabric swatch:

- Temperature: 300–325°F (149–163°C)

- Pressure: Medium to high (firm, even pressure)

- Press Time: 10–15 seconds

- Peel Type: Cold peel (allow full cool-down before removing film)

- Post-press: Optional 5–10 seconds to lock in durability

Tip: Always test one press for your exact shirt fabric and heat press model. Lighter poly blends often prefer the lower end of the temperature range.

Artwork and File Prep Best Practices

- Use high-resolution artwork, ideally 300 DPI at final print size.

- Save as PNG or TIFF with transparent background for single designs.

- Keep fine lines at least 0.25 pt and avoid hairline fonts.

- Use RGB or CMYK color space, but expect slight color shifts — order a proof if color matching is critical.

- For multiple small items, gang sheets can save money, but individual transfers are often cheaper and faster.

For detailed file guidelines and press instructions, see Five Star DTF’s step-by-step instructions page: https://fivestardtf.com/instructions/

Pressing Tips for Consistent Results

- Pre-press the garment 2–3 seconds to remove moisture and wrinkles.

- Use a silicone or Teflon sheet if you want extra protection, but it’s not always necessary.

- Align the transfer carefully; center and placement guides help maintain consistency across runs.

- Cold peel ensures the adhesive fully sets and reduces edge lift.

- Always launder samples before mass production to confirm wash durability.

When to Choose Cotton vs Polyester for Your Product Line

- Choose cotton if your customer wants a soft, breathable everyday tee.

- Choose polyester for performance wear, moisture-wicking gear, or athletic jerseys.

- For mixed runs, DTF lets you print the same design and press it onto both fabric types with minimal adjustments.

Troubleshooting Common Problems

- Ghosting or blurring: Check film feed and printer calibration, and confirm proper curing of adhesive powder.

- Edge lift: Increase pressure slightly or add a 5–10 second post-press.

- Shine on polyester: Lower temperature or reduce dwell time; ensure you pre-press to remove moisture.

- Color fade: Confirm inks were fully cured before pressing; post-press can help.

Pricing, Turnaround, and Production Notes

If you’re running a small business and need fast, reliable service, Five Star DTF offers same-day printing when orders are placed by 1 PM MST, plus free shipping on orders over $100. No minimums and no setup fees make DTF ideal for prototypes, single-run orders, and small batch production.

Order direct-to-film transfers or explore specialty options like glitter DTF prints and UV DTF stickers from the Five Star DTF storefront:

- Order DTF Transfers: https://fivestardtf.com/product/dtf-transfers/

- UV DTF Stickers: https://fivestardtf.com/product/dtf-stickers/

- Glitter DTF Transfers: https://fivestardtf.com/product/glitter-dtf-transfers/

FAQs

How durable are DTF prints on cotton and polyester?

DTF prints are very durable. When pressed correctly and washed inside-out on gentle cycles, you can expect 100+ wash durability with no cracking or major fading.

Do I need a different press setting for polyester?

You may want to lower the temperature slightly and reduce dwell time for 100% polyester to avoid sheen or melting. Always run a swatch test first.

Can DTF print bright whites on dark polyester jerseys?

Yes. DTF uses a white underbase printed with the design to deliver bright whites and strong color saturation on dark fabrics, including polyester.

Are there minimum orders for DTF transfers?

No, Five Star DTF offers no minimums and no setup fees, making it perfect for one-offs and small batch runs.

What file types work best for DTF printing?

High-resolution PNG or TIFF files with transparent backgrounds are preferred. Vector files like AI or EPS also work for scalable graphics.

How fast can I get my order if I’m in Arizona?

Five Star DTF prints same-day for orders placed by 1 PM MST and offers local pickup in Tempe, with fast statewide and nationwide shipping.

Practical Use Cases and Examples

- Boutique brands that sell both cotton tees and poly athletic wear can use one DTF design file and press the same transfer with small press adjustments.

- Print shops offering team uniforms can produce photo-quality logos on UV-stable polyester fabrics without complex pre-treatments.

- Etsy sellers benefit from low minimums and same-day printing for seasonal runs and last-minute orders.

Local Pickup and Ordering

Five Star DTF is Arizona-based and offers convenient local pickup in Tempe. For quick ordering and same-day options, upload artwork and place your order on the product page: https://fivestardtf.com/product/dtf-transfers/

Phone support and local pickup details are available via the contact page: https://fivestardtf.com/contact/

Ready to Print? Here’s the Next Step

If you’re ready to produce press-ready artwork that works across cotton and polyester, upload your files and choose same-day printing at Five Star DTF. Fast turnaround, no minimums, and free shipping over $100 make it easy to scale.

Order online: https://fivestardtf.com/product/dtf-transfers/

📍 Local pickup: 305 S Rockford Dr Ste B, Tempe, AZ 85281

Summary

DTF is a versatile, high-quality method for printing on both cotton and polyester. With the right artwork, heat-press settings, and a trusted print partner, you’ll get vibrant, durable prints that meet small-batch and production needs alike.

About Five Star DTF

Five Star DTF is Arizona’s leading provider of

DTF transfers, Glitter DTF prints, UV DTF stickers,

and Sublimation transfers — offering same-day printing, fast nationwide shipping,

and convenient local pickup in Tempe, Arizona.

We proudly serve Tempe, Scottsdale, Phoenix, Mesa, Gilbert, Chandler, and all of Arizona,

helping creators, apparel brands, small businesses, and print shops produce premium, press-ready transfers with

vivid color, soft stretch, and long-lasting durability.

There are no setup fees, no minimum orders, and turnarounds are always fast.

Our Top Products

- DTF Transfers

- Glitter DTF Transfers

- UV DTF Stickers

- Sublimation Transfers

- Press Instructions & Tips

- Contact & Local Pickup

Artwork Help

Need your artwork cleaned, fixed, resized, or made print-ready? We offer background removal, vectorizing, color correction, and gang sheet layout.

Ready to Print?

Order DTF Transfers or

Upload Your Artwork to get started today.

All orders over $100 ship free — printed in Tempe, AZ and shipped statewide and nationwide.